How to Select a Chemical Process Pump

1.Fully Understand the Fluid Properties

The physical and chemical characteristics of the handled fluid form the first and most critical step in pump selection. These properties directly determine materials, sealing systems, and structural design.

1.1 Basic Fluid Characteristics

Clearly specify the medium name and composition (e.g., whether it contains corrosive substances), concentration, and toxicity level; whether it contains solid particles, whether it is prone to crystallization, etc.

1.2 Key Physical Parameters

Medium DensityA key parameter for calculating head and shaft power.

Medium TemperatureDetermine the pump structural configuration (foot-mounted or centerline-supported), seal type (spring seal or bellows seal), as well as the flushing scheme, cooling scheme, pump materials, etc.

Medium ViscosityDetermine the pump configuration (open impeller or closed impeller), the seal type and flushing scheme, as well as the converted water test parameters and the matched motor power (pump performance correction is required when the viscosity exceeds 20 mm²/s).

1.3 Chemical Compatibility

Evaluate fluid corrosiveness (acid/alkali concentration, chloride content, etc.) to select appropriate materials:

Confirm the corrosiveness of the medium (such as acid/alkali concentration and chloride ion content) to select suitable materials for key components including the pump casing, impeller, and shaft (e.g., for strong corrosion, Hastelloy, duplex stainless steel, or titanium alloys may be used; for mild corrosion, 304/316 stainless steel; and for non-corrosive media, carbon steel).

2. Lock in Process Parameters

Process parameters are the foundation of pump selection. They must reflect actual operating conditions and fluctuations to prevent inefficient operation or premature damage.

2.1 Inlet & Outlet Pressure

Determines:

Pump type

Seal structure

Material selection (pressure rating of casing and sealing system)

2.2 Flow Rate & Head

Determine the pump series and model specification.

2.3 Net Positive Suction Head Available (NPSHa)

NPSHa is the net positive suction head (NPSH) determined by the pump system (based on the liquid at rated flow rate and normal pumping temperature), also known as the system NPSH or effective NPSH.It is especially critical for volatile or vaporizing fluids.

NPSHa affects decisions such as:

Horizontal pump vs. vertical can pump

2-pole vs. 4-pole motor speed

Whether an inducer is required

To avoid cavitation:

To prevent cavitation in the selected pump, the condition NPSHa > NPSHr must be satisfied; standards typically require a minimum safety margin of at least 0.6 m.

3. Configuration Selection

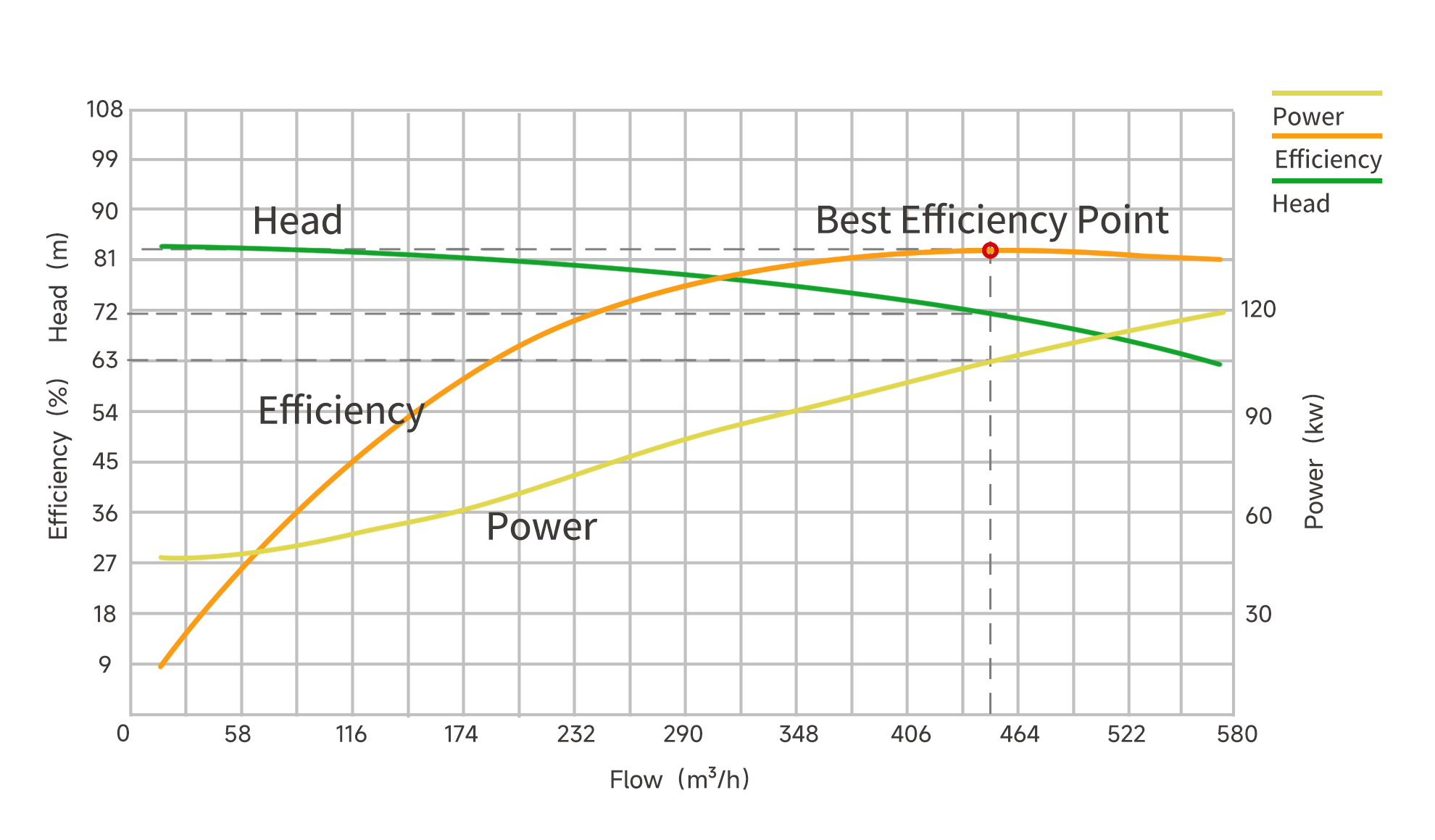

3.1 Performance Curve Selection

Rated flow should be close to the Best Efficiency Point (BEP)(API 610 recommends operating within 80–110% of BEP flow)

Avoid operating on the right side of BEP, where:

NPSHr rises rapidly

Cavitation risk increases

Efficiency drops

Motor overload may occur

3.2 Pump Type, Material s & Sealing

Select pump type based on flow, head, and fluid characteristics

Match materials for key components (impeller, shaft, wear rings)

Choose appropriate seal flushing and cooling plans according to the medium

3.3 Motor Selection

Motor selection should be based on the shaft power, taking into account a safety factor, operating conditions, and environmental factors, to avoid motor overload or energy inefficiency:

Consider:

Explosion-proof rating

Insulation class

Temperature rise limits

Environmental conditions:

Outdoor (W), High altitude (G), Anti-corrosion (F1/F2),Offshore (H), Tropical (T), Humid tropical (TH), Dry tropical (TA)

Special motor requirements:

Variable frequency motors

Dust explosion-proof motors

Energy efficiency class compliance

3.4 Instrumentation Options

Depending on operating conditions and customer requirements, select:

Vibration monitoring

Temperature sensors

Pressure gauges

Level instruments

These enable local and remote monitoring of pump unit operation.

Conclusion

Chemical pump selection is a systematic engineering process that must balance:

Fluid compatibility

Process suitability

Operational efficiency

Safety and reliability

Only by accurately controlling every parameter and matching every detail can pumps operate stably, efficiently, and cost-effectively in industrial applications.