The Difference Between Single-Stage and Two-Stage Liquid Ring Pumps?

In vacuum systems, a common question we hear is: what’s the difference between single-stage and two-stage liquid ring vacuum pumps?

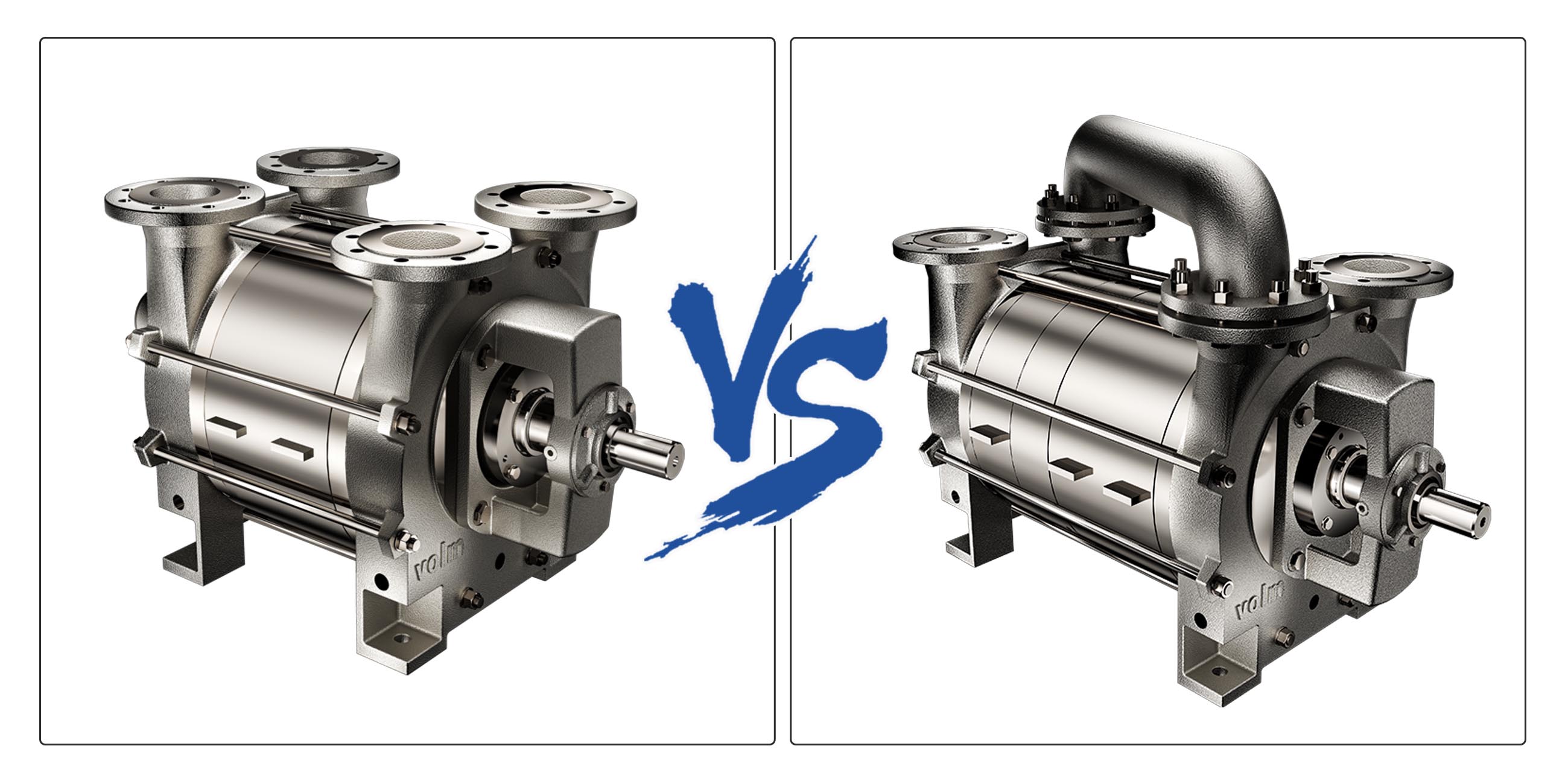

1.Single-Stage Liquid Ring Pumps

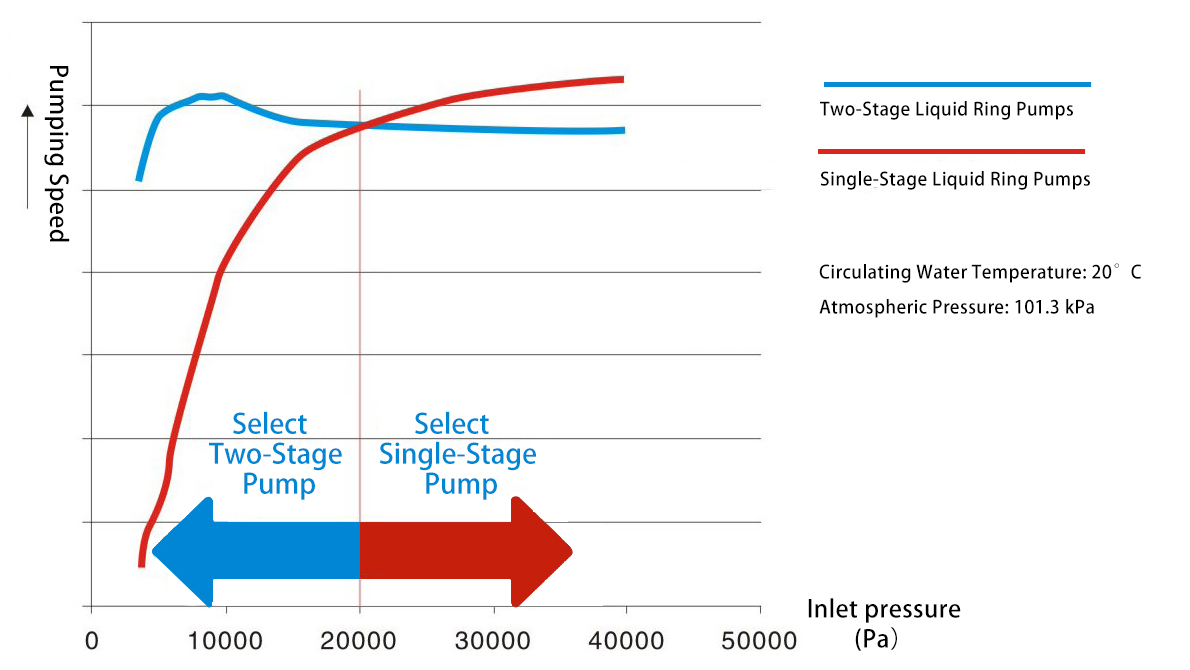

Single-stage pumps have a simple design, with a single impeller handling both suction and compression. They offer high pumping capacity and cost-efficiency under rough vacuum conditions.

However, as vacuum levels drop below 20 kPa.A, the pumping speed of single-stage pumps declines significantly. In the 5–10 kPa.A range, pumping speed can fall to less than 30% of the maximum, resulting in low efficiency and higher energy consumption.

2.Two-Stage Liquid Ring Pumps

Two-stage pumps overcome this limitation by using two impellers in series. Gas is first compressed by the first stage and then further compressed by the second, delivering higher vacuum levels and more stable pumping speed under demanding conditions.

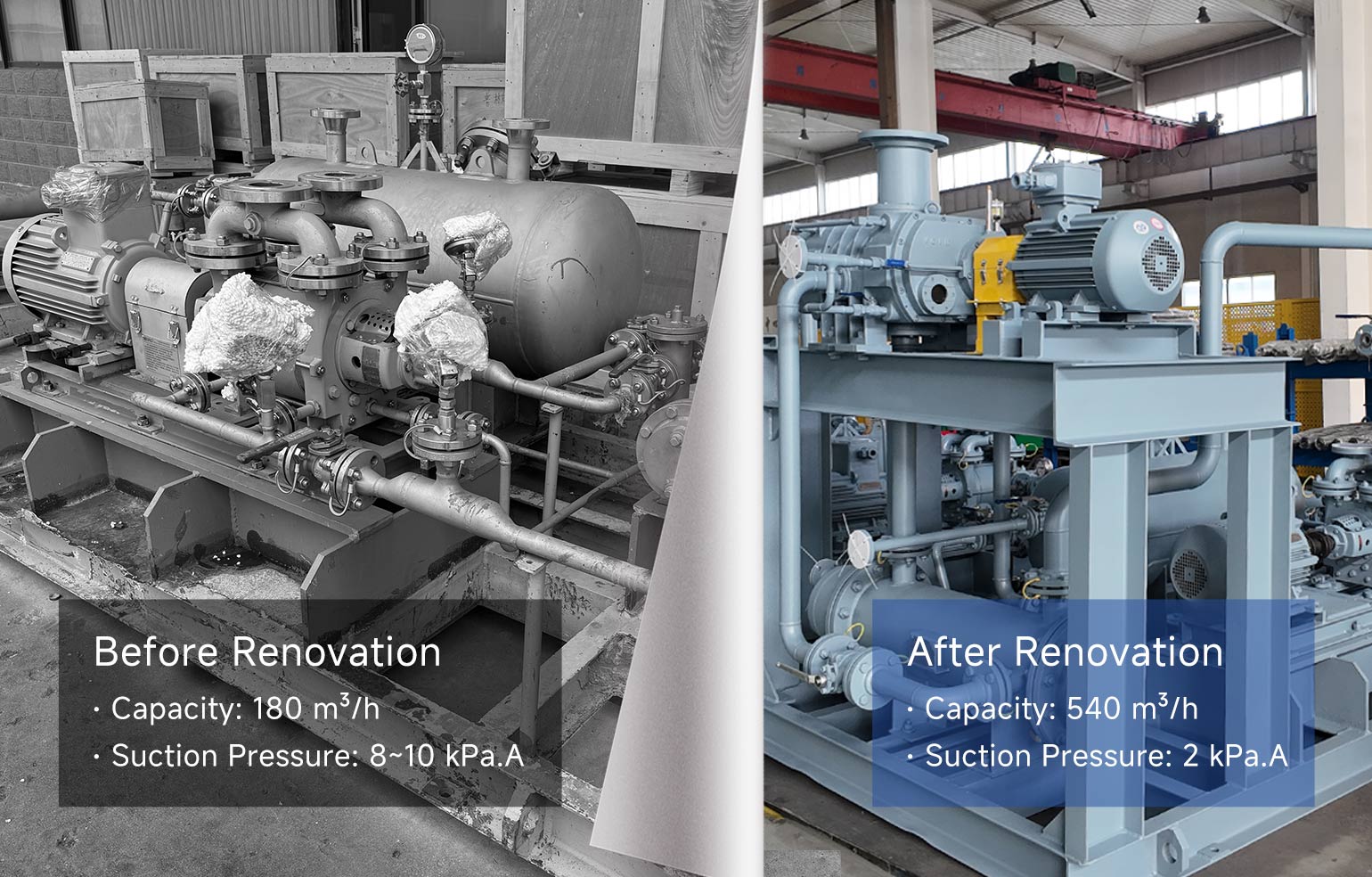

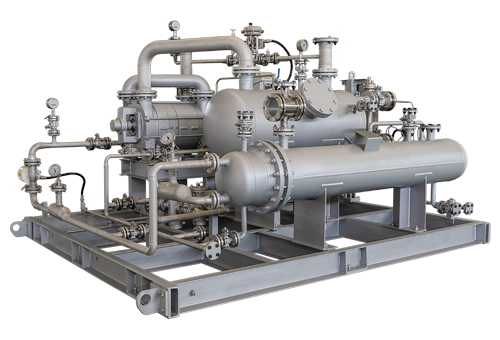

Real-World PVC Production Case: Volm 2BE1S Two-Stage Vacuum Pump

Splits a single-stage compression ratio of 1:10 into two stages of 1:5

Optimizes gas flow between stages with an inter-stage guide chamber

Increases pumping speed by 40% at 5 kPa.A compared to single-stage pumps

Improves efficiency from 25% to 45% and reduces energy consumption by 10%

In a vacuum drying process (8.5 kPa.A, 800 m³/h), the two-stage pump saves 15 kWh per day compared to a single-stage pump, resulting in annual energy savings of over ¥96,000.

Conclusion

Single-stage and two-stage pumps are designed for different operating conditions. Selecting the right pump for your process ensures energy-efficient, reliable operation.

Need help choosing the most suitable liquid ring vacuum pump for your application?

Contact VolmPump-WhatsApp: +86 187 2169 5504, Email: overseas@volm.com.cn, Website: en.volm.com.cn