High energy consumption in corn processing? Protein denaturation issues? The solution lies in Vacuum Technology!

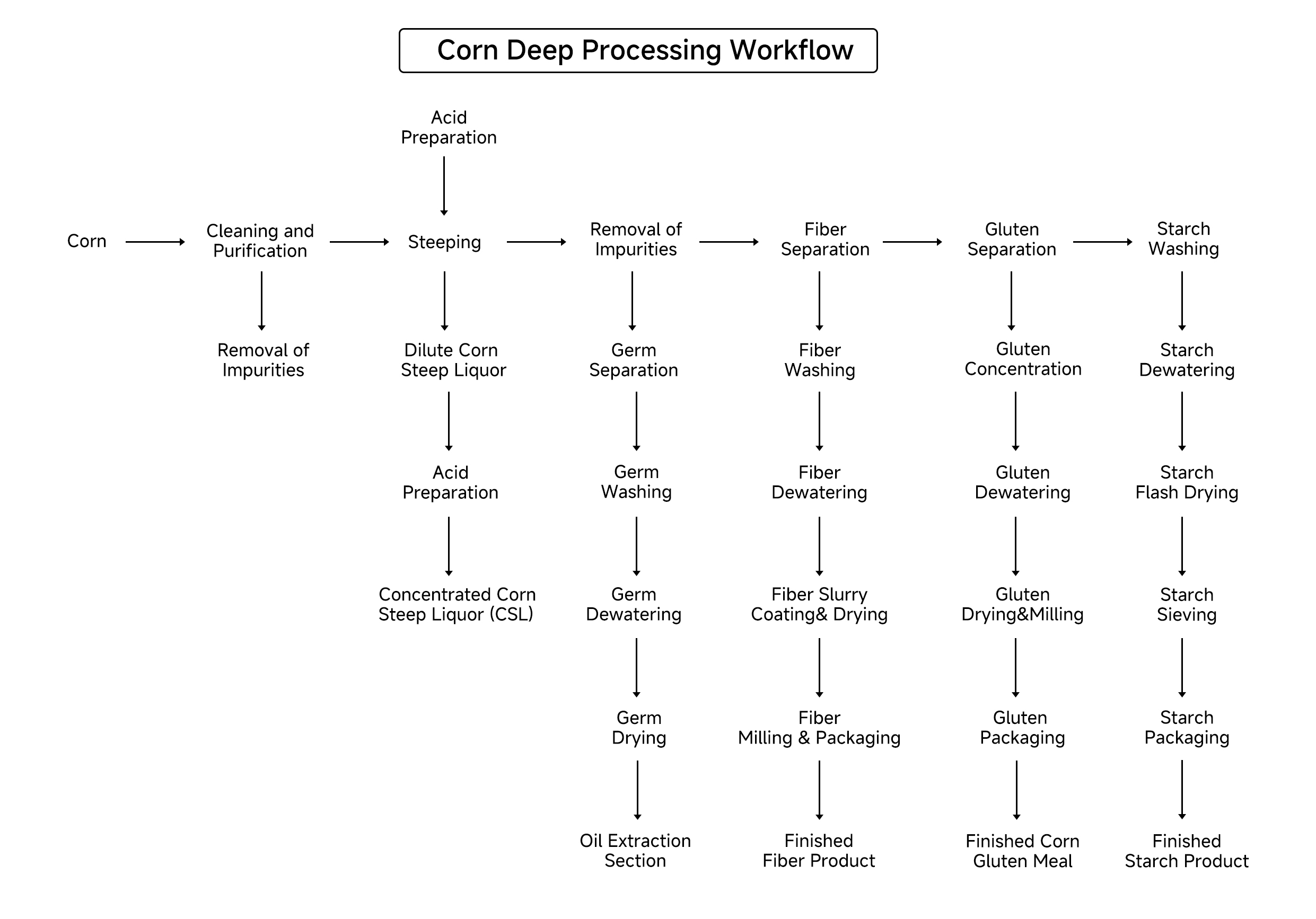

In the corn deep-processing industry, where improving efficiency, reducing energy consumption, and maximizing value are ongoing priorities, every step—from corn steep liquor concentration and fiber dewatering to protein purification and starch separation—directly impacts product quality and cost. Behind these processes, one “invisible” technology plays a critical role: vacuum technology.

By creating a stable negative-pressure environment, vacuum systems can significantly lower the boiling point of materials, enhance evaporation efficiency, protect heat-sensitive components, and dramatically reduce energy consumption and operational costs.

In this issue, we take a deep dive into four core corn processing scenarios, revealing how vacuum technology empowers the corn deep-processing industry.

Core Application Scenarios and Vacuum Requirements

01 Corn Steep Liquor Evaporation and Concentration

Vacuum concentration of corn steep liquor (CSL) is an efficient and energy-saving technology widely used in feed, food, and fermentation industries. It lowers the boiling point under vacuum, reducing thermal degradation of heat-sensitive components (proteins, sugars, vitamins), while significantly improving evaporation efficiency.

1. Principle of Vacuum Concentration

(1) Boiling Point Reduction

At atmospheric pressure, water boils at 100 °C. Under vacuum conditions (–0.06 to –0.09 MPa), the boiling point drops to 40–60 °C, minimizing damage to heat-sensitive nutrients in CSL and corn protein slurry.

Suitable for heat-sensitive materials such as corn steep liquor and corn protein slurry.

(2) Enhanced Evaporation Rate

Vacuum concentration increases evaporation rates and reduces energy consumption, achieving 30%–50% energy savings compared to atmospheric evaporation.

2.Role of the Vacuum System

The vacuum system lowers the boiling point through negative pressure (typically –0.06 to –0.08 MPa), minimizing thermal degradation of nutrients and making it ideal for high-value-added products.

02 Corn Fiber Dewatering

Corn fiber dewatering removes excess moisture from fiber slurry, improving dry matter content and directly impacting product value, energy efficiency, and transport cost.

1. Pressure Screens & Screw Presses

Corn fiber slurry is first separated by pressure curved screens (operating pressure ~0.4 MPa) and then further dewatered by screw presses. Regular inspection prevents clogging and operational issues.

2. Centrifugal Dewatering

Some processes use centrifuges to separate fiber and steep liquor. The resulting fibers are soft, plastic, and have reduced moisture content.

3. Vacuum Belt Filter Press

Used for high-moisture fiber materials, achieving stable post-dewatering moisture content. Role of the vacuum pump in a corn fiber belt filter press:

The vacuum pump generates negative pressure (typically –0.06 to –0.08 MPa) to drive the solid–liquid separation process, drawing water from the corn fiber slurry through the filter cloth while retaining the solid fibers as a filter cake.

When integrated with a belt filter press, the stability of the vacuum pump directly affects dewatering efficiency. After vacuum dewatering, corn fiber achieves a dry matter content of 48%–55%, meeting the requirements for subsequent drying or feed production.

03 Corn Gluten Protein Concentration

The corn protein concentration process involves physically removing water from dilute corn protein liquid to significantly increase protein content, ultimately producing corn protein powder, commonly known as corn gluten meal (CGM). This protein powder typically contains over 60% protein, making it a high-quality feed ingredient, and it can also be further refined for use in the food industry.

1. Membrane Separation Technologies

(1)Ultrafiltration (UF)

Effective for proteins (MW 500–50,000), achieving high recovery with mild conditions to preserve protein activity.

(2)Nanofiltration (NF)

Concentrates low-MW peptides (200–2,000), often combined with reverse osmosis (RO) to remove impurities and enhance protein purity.

(3)Disc-Stack Centrifugation

Concentrates dilute protein (15–25 g/L) to 80–110 g/L prior to dewatering.

2. Freeze Concentration

Vacuum-assisted freezing lowers boiling points (40–60 °C at –0.06 to –0.09 MPa), protecting proteins and vitamins from heat damage.

3. Vacuum Evaporation (Core Step)

Low-temperature concentration is carried out using a three-effect falling film evaporator, increasing the solids content of the separated liquid to 40%–50% while minimizing denaturation of heat-sensitive proteins.

(1) Operating Principle

The vacuum pump reduces the pressure inside the evaporation system (typically –0.06 to –0.095 MPa), significantly lowering the boiling point of the liquid to 40–60 °C. At these reduced temperatures, water evaporates efficiently while minimizing denaturation of heat-sensitive proteins.

Multi-effect evaporators further enhance energy efficiency by reusing the latent heat of secondary vapor. For example, steam consumption in a three-effect evaporator is only about one-third of that in a single-effect system, making it ideal for large-scale continuous concentration of corn syrup or protein solutions.

(2) Key Advantages

Low-Temperature Protection: Prevents protein denaturation caused by high temperatures, preserving functional properties such as the film-forming ability and antioxidant activity of corn alcohol-soluble proteins.

High Efficiency and Energy Saving: Vacuum concentration achieves higher evaporation rates with lower energy consumption.

Environmental Friendliness: The closed system minimizes wastewater and gas emissions, complying with green factory standards.

04 Corn Starch Dewatering

The starch dewatering process involves mechanically removing most of the free water from starch slurry, converting it from a liquid slurry into wet starch cakes (filter cakes) in preparation for cost-effective and efficient final drying.

1. Main Dewatering Equipment and Operating Principle

The primary and preferred equipment for starch dewatering in the industry is the rotary drum vacuum filter. Its operation can be likened to a continuously running “industrial vacuum cleaner,” with the core driving force provided by the negative pressure generated by a vacuum pump. Solid–liquid separation is achieved through vacuum suction, making it suitable for dewatering washed starch or removing impurities from saccharification liquids. The process is continuous and automated, and mainly includes the following stages:

(1) Formation of Precoat Layer

Starch slurry is drawn onto the surface of the drum by vacuum suction, forming a precoat layer composed of starch particles and filter cloth, which acts as a filtration medium to enhance separation efficiency.

(2) Filtration and Dewatering

Filtrate passes through the precoat layer and filter cloth and is discharged via the distribution valve of the suction pipe, while solid starch particles are retained to form a filter cake. Some equipment features a folded-belt design, where the filter cloth moves with the drum, is discharged via guide rollers, and simultaneously washed for reuse.

(3) Discharge and Cleaning

The filter cake is scraped off (moisture content can be reduced to below 40%), and the filter cloth is cleaned with high-pressure water and recycled for continuous use.

2. Role of the Vacuum Pump in a Rotary Drum Filter

The vacuum pump serves as the core power source of the rotary drum vacuum filter. By drawing air from inside the drum to create negative pressure (pressure differential), it drives the solid–liquid separation of starch slurry. The pump’s performance directly affects filtration efficiency, filter cake moisture content, and energy consumption.

On the path toward efficient, green, and high-value corn processing, vacuum pumps may operate “behind the scenes,” but they are key to process performance and product quality.

Choosing the right vacuum pump means securing continuous production and unlocking higher profitability.

In our next issue, we will share real case studies showing how Volm vacuum pumps act as the “invisible engine” of production lines—letting results speak for themselves and making value visible. Stay tuned!

Leave a comment or contact us to learn more about industry solutions and product information.

Free Technical Consultation

Visit Our Factory to Witness Micron-Level Manufacturing

Schedule a Visit to Volm Factory

Witness micron-level processing centers and ISO 9906 Class-1 testing center up close

Customize for You

Help customers save 30% costs on average

Reduce failure rates by 40% on average