Efficiency Boost in Chemical Production: Volm DML Air-Cooled Roots–Liquid Ring Vacuum System Retrofit

Project Background

A chemical company in South China previously relied on a liquid ring pump from another brand. However, its limited performance significantly restricted production capacity.

The pump delivered only 180 m³/h at a suction pressure of 8–10 kPa.A, which failed to meet process requirements for stable and continuous operation.

To address this issue, Volm implemented a targeted retrofit solution — integrating a DML Air-Cooled Roots Pump into the existing liquid ring system, forming a high-efficiency Roots–Liquid Ring Vacuum System.

Upgrade Solution

Once the liquid ring pump pre-evacuated to 20 kPa.A, the DML Roots pump automatically engaged, rapidly enhancing overall performance.

This hybrid system significantly improved the plant’s vacuum efficiency and production stability.

Key Upgrade Results:

Pumping capacity: Increased from 180 m³/h to 540 m³/h

Ultimate suction pressure: Improved from 8–10 kPa.A to 2 kPa.A

Vacuum stability: Greatly enhanced for continuous operation

Technical Advantages of the DML Air-Cooled Roots Pump

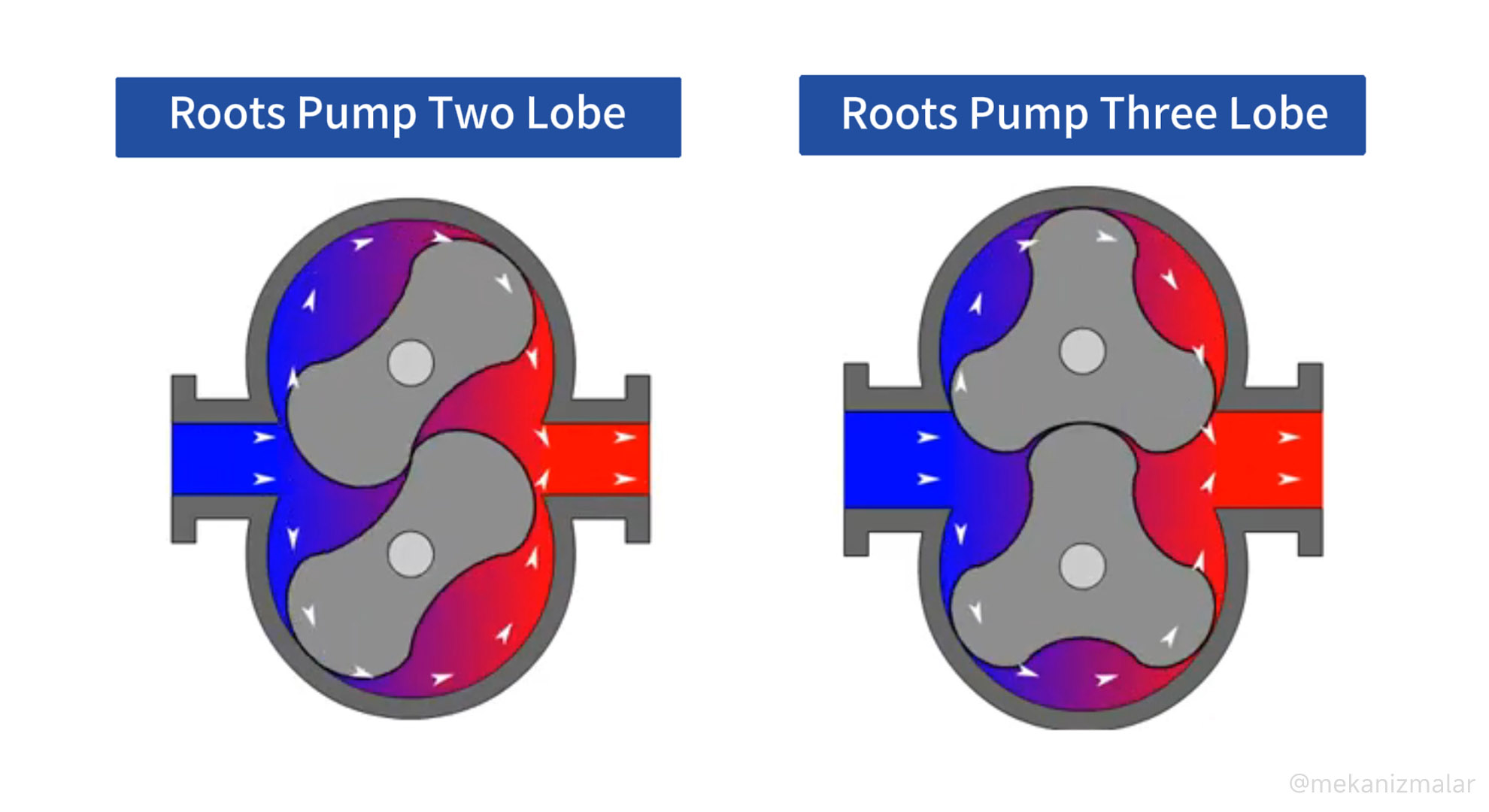

1. Two-Lobe Wide-Head Rotors

Provide a longer sealing line than traditional three-lobe designs, minimizing internal leakage and preventing backflow of process media.

2. Integrated Discharge Condenser

Effectively lowers exhaust temperature and extends equipment lifespan.

3. Corrosion-Resistant Construction

The pump body is made of cast iron with a Hastelloy coating, providing excellent durability and corrosion resistance for harsh chemical environments.

Performance Verification

Original liquid ring pump capacity: 180 m³/h

After DML integration: 540 m³/h, suction pressure improved to 2 kPa.A

Vibration (GBT 29531-2013 limit ≤2.8 mm/s): Measured only 0.79–1.20 mm/s

Temperature rise (limit ≤40°C): Measured only 17.4°C at 14°C ambient

Noise level: ≤85 dB, fully compliant

Conclusion

Volm’s Roots–Liquid Ring Vacuum Systems combine the strengths of both pump types, providing:

High efficiency and stable operation

Extended service life under harsh process condition

Proven performance across chemical and industrial sector

This retrofit project demonstrates Volm’s capability to deliver tailored, high-efficiency vacuum solutions for the chemical industry and beyond.

Free Technical Consultation

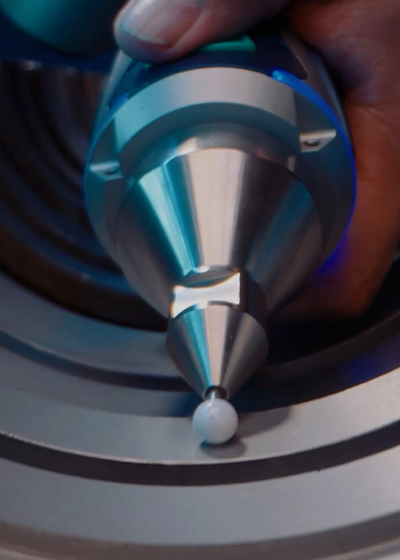

Visit Our Factory to Witness Micron-Level Manufacturing

Schedule a Visit to Volm Factory

Witness micron-level processing centers and ISO 9906 Class-1 testing center up close

Customize for You

Help customers save 30% costs on average

Reduce failure rates by 40% on average